However, the price is steep, almost double that of other DLP resin 3D printers.

As the testing progressed, it was obvious how much more this printer had to offer.

The entire chamber is heated to ensure the best possible resin consistency throughout the print process.

Uniformation has also added a filter to help keep the environmental air free from the usual smell of resin.

It is essentially a standard8Kresin printer that uses an LCD panel to cure the resin.

This printer is now capable of appearing on cheaper machines.

Still, the machine’s size and weight reinforce its absolute build quality.

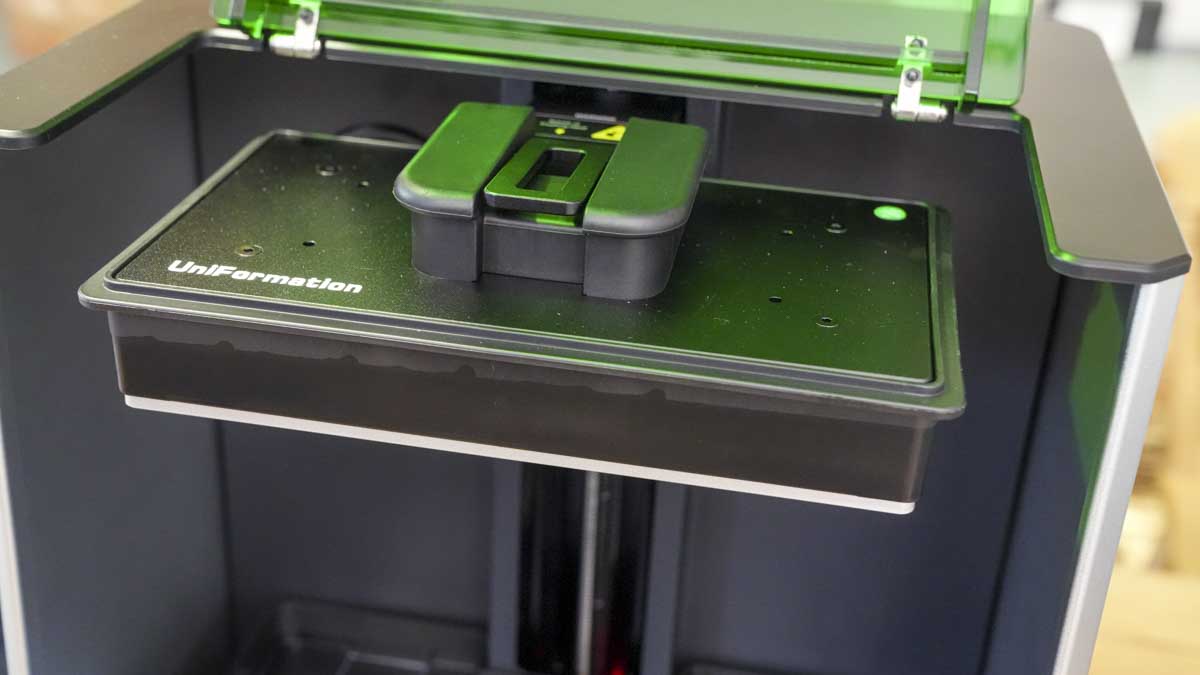

The resin tank sits on the base of the machine and covers the 8K LCD screen.

Unlike some of the latest machines, this tank needs to be manually filled to level before printing.

Overall, the design is solid and high-quality.

Jewellers and product designers will also benefit from the slightly larger-than-average build volume.

This means that the printer has wide compatibility with most standard 3D print resins.

To do this, however, takes some knowledge of the Prusa slicer web link parameters.

However, for some users, the advanced details of that tool can initially be a little daunting.

Although Uniformation ships the printer with GKtwo Slicer, you also have the choice of using the excellent Chitubox.

The UniFormation GKtwo has already garnered quite a following due to the machine and print quality.

During the print process, two non-print-related aspects really stood out with this printer.

The first was the smell or lack of it.

The second is that the printer works without issue, even in cold weather.

The print quality itself is outstanding once the prints have been properly cleaned and all supports removed.

This issue is purely down to the jot down of resin used rather than the printer.

It’s also the printer that I would recommend for any business needing a production-quality model.

The first of the points around performance is the workflow.

While other printers are quickly catching up, they’re still far from the absolute ease of use.

Generally, the prints came out relatively clean and ready for use.

Under a bright light, the prints can then be inspected and cleaned before curing.

For me, the real advantage of Form 3+ is the Light-Touch Removal Support.

Should You Buy the Uniformation GKtwo?

Its lack of these modern conveniences could be a dealbreaker for users seeking a more automated 3D printing experience.

We tested thebest 3D modeling software- and these apps really bring creations to life